The refrigerator is empty and the next weekly shopping is due again. Most of the time, the products that end up in the shopping cart at the supermarket are the ones we already know and buy regularly. Nevertheless, we always take another look at the packaging before buying. The reason: we check the best-before date.

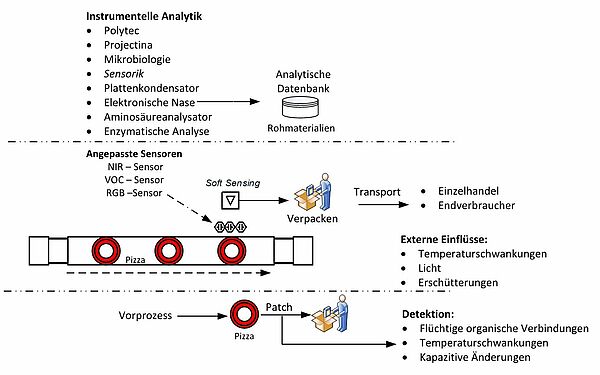

The best before date of a product is set by the manufacturer in a very general way. This is despite the fact that natural fluctuations or changing environmental conditions during the manufacturing process can lead to individual risks of spoilage. The Institute for Industrial Information Technology (inIT) together with the Institute for Food Technology.NRW (ILT.NRW) is conducting research in the project "IP3 - Data Analysis and Autonomous Prognostics to Improve Food Transparency and Safety" on ways to make the best-before date more precise. To realize this project goal, an initial concept for possible sensor systems has now been developed:

"With the help of various analytical instruments, such as the electronic nose or an enzymatic analysis, raw materials and end products are to be observed. Over a longer period of time, indicators will thus be collected which can detect the spoilage of foodstuffs, and these data will then flow collectively into a database where they can be evaluated," says Professor Hans-Jürgen Danneel, Institute Director of ILT.NRW.

The next step is to convert the analytical instruments used into low-cost, small sensors (soft sensors). Conceivable here are NIR, VOC or even color sensors, which will find their use in a bypass system for the production line. As soon as the analysis of the sensors is completed, the generated data is automatically compared with the data from the database and a shelf life forecast can be given. However, since a frozen pizza, for example, is still exposed to transport and other external influences after finished production until it reaches the retailer and ultimately the end consumer, additional indicators must be integrated. These should be located directly on the product and be readable by the consumer. For example, the packaged product could be equipped with a QR code that displays a color scale based on temperature sensors, providing a safer and valid best-before date for the end consumer.

Another possibility for the prediction of a best-before date is the use and installation of a so-called patch in the packaging process. This patch is supposed to react to material changes and then indicate the degree of spoilage of the food by a color change. Previous storage tests have identified the optical change as a possible indicator. By using a hyperspectral camera, it was possible to specifically visualize the formation of mold.

"We can see: knowledge from the field of signal and image processing, high-dimensional data analysis, and pattern recognition methods is also highly relevant for the food industry," explains Professor Helene Dörksen from inIT. "With innovative technologies and the use of information fusion and machine learning, the best-before date can be made more precise. This not only allows us to determine more accurate and individualized dates, but would also help reduce food waste," explains Professor Volker Lohweg, Institute Director at inIT.

Future plans include the use of an electronic nose to detect the formation of volatile organic compounds (VOCs), carbon-containing substances that evaporate even at relatively low temperatures and promote mold growth.