Digitization and Industry 4.0 are currently on everyone's mind. It refers to the intelligent networking of machines and processes in industry with the help of digital technologies.

At the focus day "Where food meets IT" at the Ostwestfalen-Lippe University of Applied Sciences, the question of how Industry 4.0 can change the food industry was highlighted. How can I use suitable sensors and targeted data evaluation to continuously check and improve the quality of products? Are autonomously controlled processes in production with artificial intelligence (AI) already feasible today? Which digital solutions support a minimization of food waste? Do blockchain technologies also offer potential in the food industry?

All of these questions involve IT topics that researchers at the Institute for Industrial Information Technology (inIT) deal with on a daily basis and were thus able to provide a lot of input as experts at the focus day.

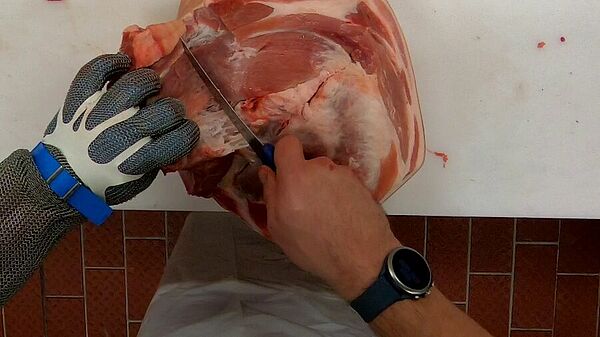

Professor Carsten Röcker, deputy director of the institute at inIT, for example, presented the opportunities and challenges of digital assistance systems in the food sector. The working world is undergoing a transformation. Assistance systems can automatically take over tasks, for example in production, or guide the employee. "Industrial assistance systems should contribute to a cognitive relief of the employees," says Professor Röcker. But how can the findings be transferred to the food sector? This is being researched at inIT with the project "FoodAssist: Basic technologies for cutting assistance systems in the food sector". The aim of the project is to investigate the transferability and applicability of existing solution approaches in the area of meat cutting. "In many butchery companies there is a high turnover of workers. Therefore, new employees have to be trained again and again. Assistance systems could be used to interactively teach these the cutting guides. This would also mitigate language and cultural barriers," says Röcker, citing just one of the advantages. However, the project is still in its infancy. Since meat is a natural product with a high degree of variance, an extremely high degree of accuracy in cutting guidance is required. Röcker explains, "Currently, we're looking at analyzing the work situation, the cutting process, and the worker's point of view. Then we have to see to what extent meat cutting can really be supported by assistance systems."

Professor Helene Dörksen, a board member at inIT, also contributed her technical expertise in a keynote presentation. She looked at intelligent authentication systems for food analysis. Data can be used, for example, to determine the degree of ripeness of fruit. Matching algorithms analyze the data and can take over human capabilities. What is obtained is a mapping of a physical object into data-transformed information. Authentication methods provide transparent results, have high precision and robustness, and real-time capability. "For example, we can use authentication systems to analyze specific bio-components such as hormones or proteins. Food production data sources include quality control or hygiene control," Professor Dörksen described.

In addition to the scientific presentations, Professor Henning Trsek and Andre Bröring from inIT also offered an interactive format at the focus day. In a 1.5-hour workshop on the topic of blockchain, they worked together with the participants to identify undreamed-of potentials for the food industry. The workshop was organized in cooperation with Jens Much from the IOTA Foundation. The IOTA Foundation develops one of the leading protocols in the blockchain/distributed ledger field. "Blockchain technology has so far been mainly applied in the financial sector and is increasingly used in the supply chain sector. Since it has not yet received much attention in the food industry, we wanted our workshop to both introduce the technology to the right people in the field and to work together on possible application scenarios and their requirements. We were able to discuss some possible approaches, as well as define advantages and disadvantages that now need to be examined in the future," says Trsek, summarizing the workshop with satisfaction.

Bundled expertise is located in Lemgo to drive forward the digitalization of the food industry. "The focus day once again made it clear how much collaboration between different disciplines is worth. However, it is always important that we do not want to drive digitization as an end in itself. There must always be a beneficial purpose behind it and, for example, make production more effective. We are noticing that more and more companies are seeing the potential and opportunities offered by digitization, and that this is giving rise to collaborations," says a delighted Professor Volker Lohweg, the institute's director.