TEIG 4.0: Process optimization in the field of wheat dough processing using AI-based methods - "Real-time detection of quality-relevant characteristics in raw materials, intermediate and end products".

Previous processes in wheat dough processing are often artisanal. This leads to significant fluctuations in product quality. Extensive automation, in the long term self-regulating processes, can reduce these fluctuations. It is important that parameters and target values recognized as important, first and foremost product quality, are continuously monitored.

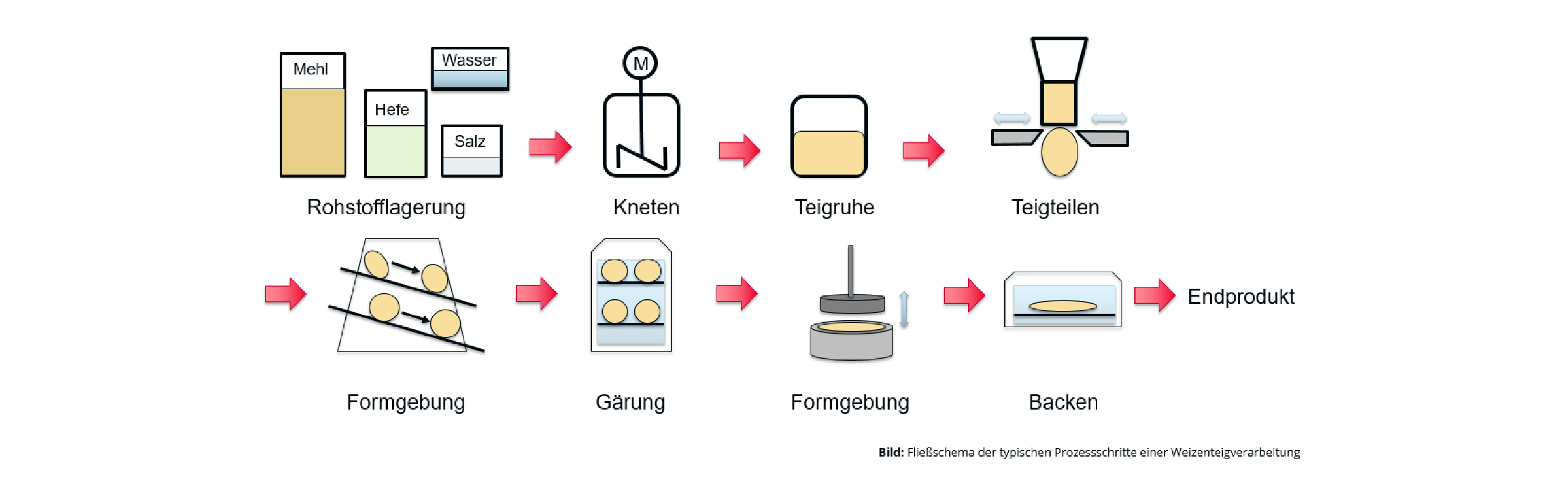

The project focuses on industrial application and aims at results that are of high practical relevance. To understand the complex interactions, the entire dough processing process from raw material to baked dough piece is recorded.

The data is analyzed using methods based on artificial intelligence (AI). By applying a combination of machine learning (ML) and information fusion (IFU) methods, relationships between wheat dough properties, process parameters and product qualities are analyzed and visualized.

The aim is to use inline-capable measurement technology to record raw material and intermediate product properties in wheat dough processing already during the production process and to evaluate them in real time. This minimizes waste, protects resources, and prevents food wastage.