FOAsK: Flottenweite Optimierung des Ressourcenverbrauchs und Steigerung der reinigungszeitbezogenen Verfügbarkeit von Kanalreinigungsfahrzeugen

When cleaning sewers, the task is to loosen the organic and mineral impurities (domestic food waste, sand, gravel, tar, bitumen, etc.) contained in them from the sewer wall and suck them out. For this purpose, so-called combined sewer cleaning vehicles are used.

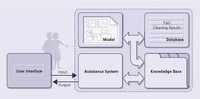

The FOAsK project relies on a Bayesian Predictive Assistance System (BPAS), which provides decision support to the operator for cleaning parameter settings.

By using data from the entire vehicle constellation, FOAsK aims to select the optimal parameterization and thus achieve consumption-optimized vehicle operation.

Through the targeted development of a measurement value acquisition system, the solid and water volume fractions in the sludge chamber will be determined separately. This will provide a calculation basis for resource- and time-effective vehicle use.

Also in this project an exchange of information concerning the parameterization between the vehicles will be implemented. Thus, the learned correlations of vehicle characteristics, environmental data, channel characteristics and flushing data will be generalized and used for a wide range of vehicles and channel types.

Based on fleet-wide experience, optimization of the assistance system will be implemented. Each vehicle will benefit from the experience of the other vehicles.